Finding the best Sealing Solution for Industrial Applications can be a complex design process incorporating many different operating challenges. The Industrial Seal Market deals with a variety of applications, aggressive media, wider temperature range requirements, extreme pressures , and various cycle speeds.

When considering a sealing solution, many Original Equipment Manufacturers (OEM) select a traditional O-Ring as their first seal choice. Although useful in less demanding applications, elastomer O-Rings are limited in their dynamic and static conditions when temperature, pressure, fluid compatibility, and friction are factors.

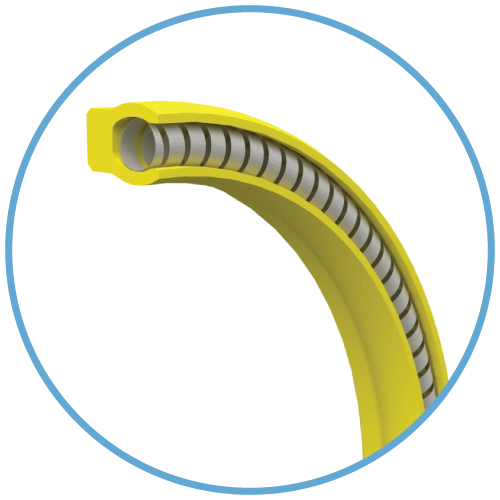

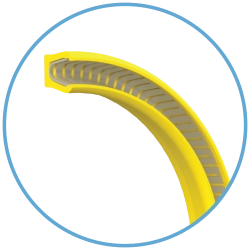

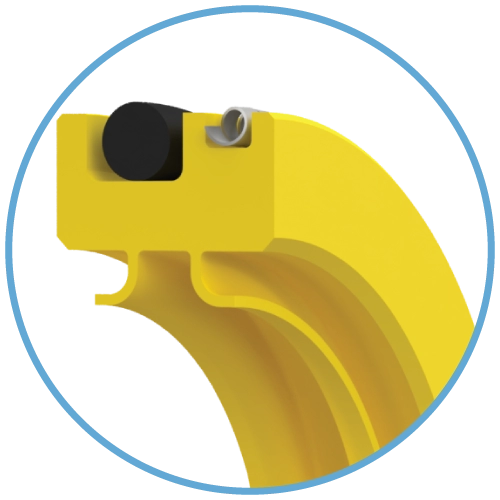

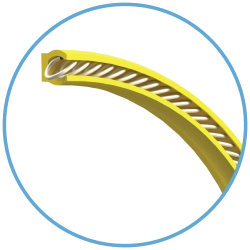

When these harsh operating factors cause seal failure many of our Industrial Sector Clients turn to more robust options in our Spring Energized Seals.

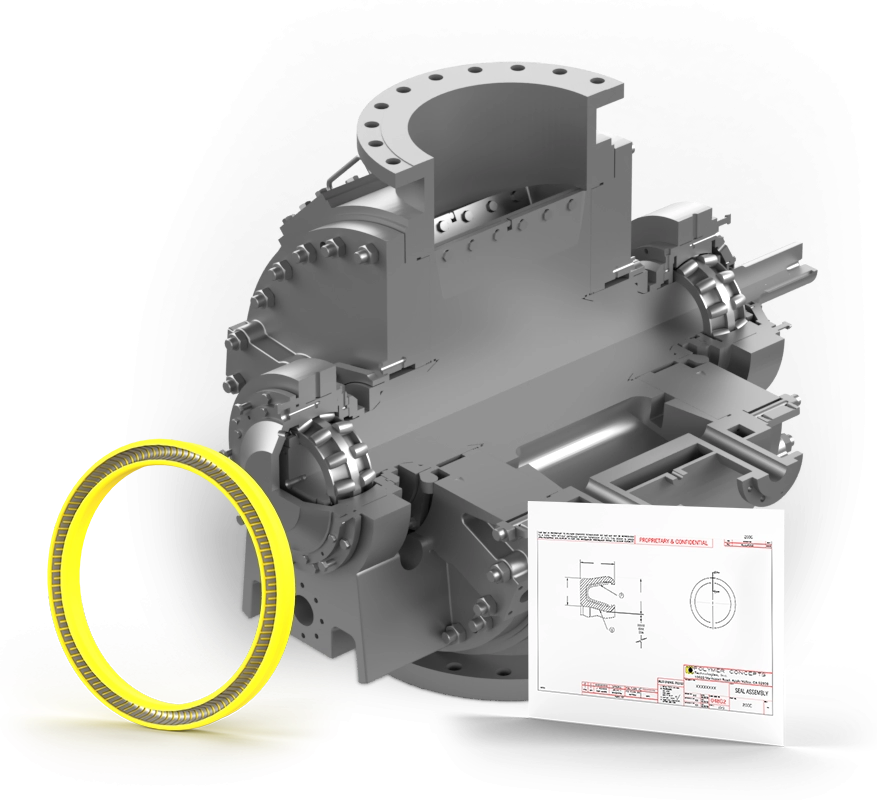

Spring Energized Seals provide a wider selection of materials to choose from. Spring Energized Seals are custom designed to the application specifications and machined to precise tolerances. With exacting precision, many of our Seal designs can provide near-zero or zero leakage and long life.

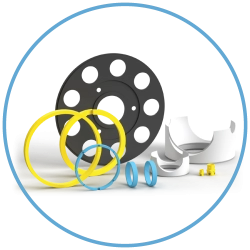

As technology advances and performance demands become greater, equipment manufacturers seek credible partners to help with application engineering, design, and manufacture of technologically advanced materials and unique seal designs for critical applications. Many of the designs for industrial applications are engineered from polymer and fluoropolymer materials and consist of spring-loaded seals, custom seals, bearings, and other components related to sealing systems.

Industrial Sealing Products & Applications

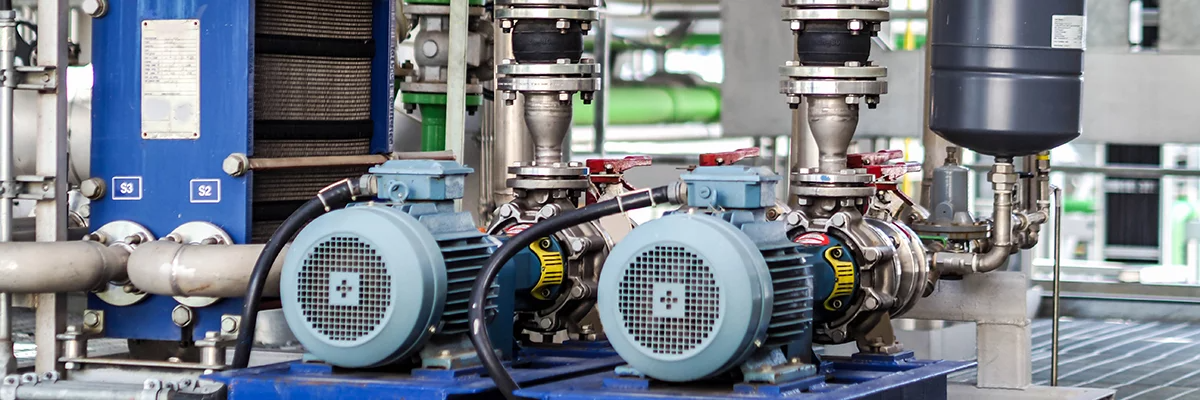

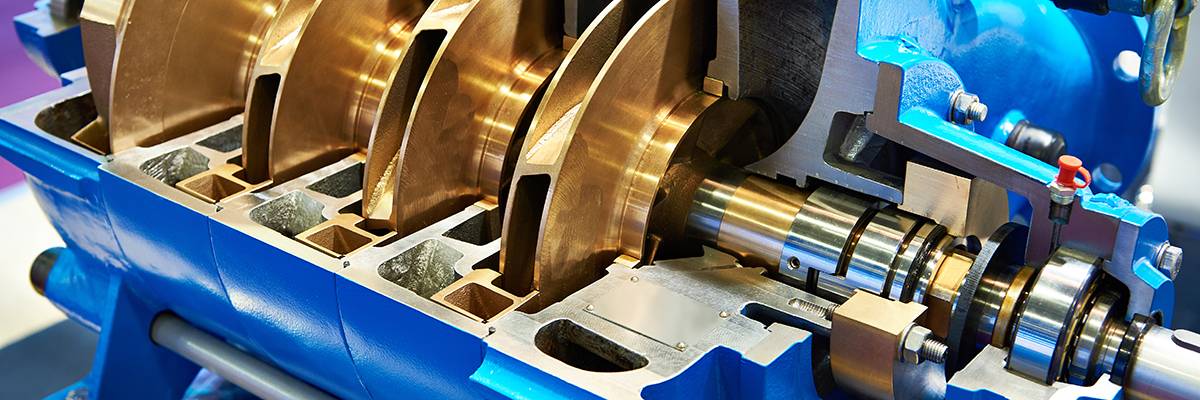

Fluid Handling Pumps

Valves

Cryogenics

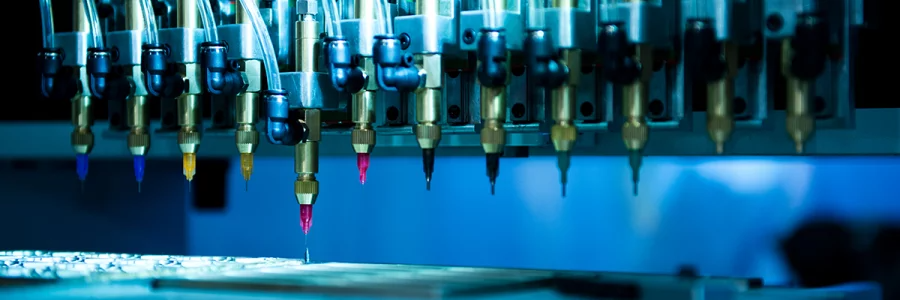

Precision Dispensing

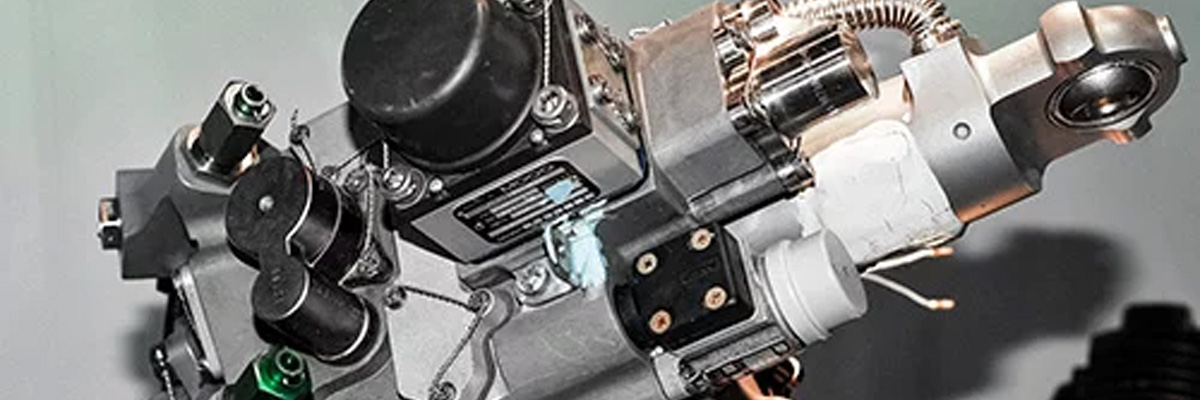

High Pressure / High Temperature

Compressors

Actuators

Gas and Fluid Handling

Rotating Equipment

Semiconductor Equipment

ENGINEERED INDUSTRIAL SEALS, FOR YOUR HIGH PERFORMANCE HARDWARE

Industrial Seal & Component Design Services

Engineered Designs

Is your current sealing solution not cutting it? Our in-house design team can help you develop one that will fit all of your operating requirements.

Seal Failure Analysis

Is your sealing solution underperforming or failing prematurely? We can help by taking a collaborative approach using our materials testing lab and applications engineering team.

Rapid Prototyping

Our facility is equipped to quickly bring your designs to prototype fruition. We offer design proposals 5 business days . Working prototypes in three weeks or less, and order to production within 4 business weeks.

Full Applications Engineering

Are you working with standard or custom sizes in your hardware? We have the experience to help you in your seal gland, and installation tool design.

Reverse Engineering

Is your seal provider experiencing long lead time, out of stock or obsolete? We offer in-house reverse engineering and manufacturing services.

Ready to Place an Industrial Design Request?

THE INDUSTRY-LEADING ENGINEERED SEAL MANUFACTURER

Polymer Concepts Technologies designs, engineers and manufactures state-of-the-art application-specific sealing solutions and high-performance polymer and fluoropolymer components. We take a collaborative technical approach with our customers and incorporate flexible designs, a vast material portfolio, and experienced manufacturing methodology to tackle the challenges of the most difficult applications. Our in-depth engineering experience, understanding of material characteristics, flexible service, rapid prototyping, and strong Total Quality Management System (AS9100D & ISO9001:2015) ensure an industry-leading solution every time.