In an era of technological advancements, the sealing industry is no exception. At the heart of this evolution is the innovative technology of spring energized seals. As the sealing industry pioneers, Polymer Concepts stands at the forefront of this revolution, bringing unparalleled expertise and quality to the table.

The Basics of Spring Energized Seals

What are Spring Energized Seals?

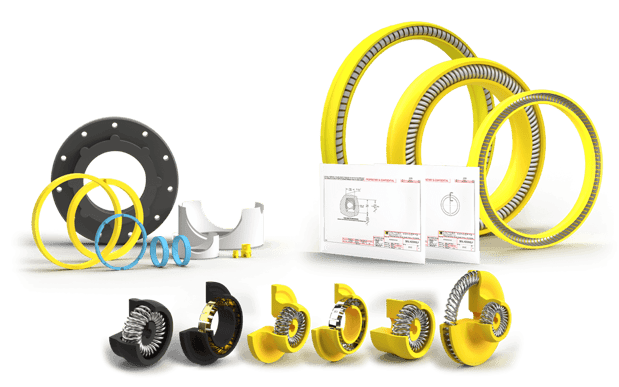

Spring energized seals, as the name suggests, employ a spring system to energize the sealing lips. This feature ensures that the seal remains effective even in fluctuating pressures and temperatures, ensuring a reliable and tight seal at all times.

Their Significance Across Industries

From aerospace to pharmaceuticals, spring energized seals cater to various sectors, offering solutions to challenges that conventional seals often can't address.

The Unique Advantages of Spring Energized Seals

Beyond their adaptability to diverse conditions, spring energized seals provide:

High Resistance

Temperature and Corrosive Environments: Spring energized seals are designed to withstand extreme conditions. They can endure a wide range of temperatures, making them ideal for applications that experience thermal fluctuations. Additionally, they exhibit excellent resistance to corrosive environments, making them suitable for use in harsh chemical contexts or where exposure to corrosive substances is a frequent occurrence.

Pressure Capabilities

Vacuum to High Pressure: These seals are adept at handling a broad spectrum of pressures, from vacuum conditions (low pressure) to high-pressure environments reaching up to 40ksi. This capability makes them versatile for various industries, including deep-sea applications, aerospace, and high-pressure processing systems.

Friction

Low and Repeatable COF: A standout feature of spring energized seals, particularly those made with PTFE, is their low and consistent coefficient of friction (COF). With a COF as low as 0.08, they provide smooth operation, minimizing wear and tear on mating surfaces and ensuring a longer service life while reducing energy consumption in dynamic applications.

Versatility

Suitable for Static and Dynamic Applications: Their design allows them to be effectively used in both static applications (such as flange seals) and dynamic applications (like rotary or reciprocating shafts). This versatility ensures that they can be applied in a wide array of machinery and equipment, offering reliable sealing solutions across various industrial sectors.

Longevity

Durable Design and Materials: Spring energized seals are known for their longevity. Their unique design, which maintains consistent sealing pressure, helps to prolong their effective life, reducing the frequency of replacements. Materials like PTFE and UHMWPE (Ultra-High Molecular Weight Polyethylene) not only contribute to their durability under operational stress but also offer an unlimited shelf life. This aspect is particularly beneficial for stock management and long-term usability, ensuring that seals maintain their properties even after prolonged storage.

Polymer Concepts' Innovations in Spring Energized Seals

Polymer Concepts isn't just a producer; they are innovators. The company has continuously pushed the envelope by:

- Tailored Solutions: Offering customized seals, specific to industry requirements.

- Quality Assurance: Rigorous testing ensures every seal stands up to the highest standards of quality and performance.

- Technological Leadership: Investing in R&D, Polymer Concepts brings advanced sealing solutions that many industries now rely on.

Applications and Use Cases

- Aerospace: With varying pressures and temperatures, the aerospace industry demands seals that can endure. Polymer Concepts has been instrumental in supplying seals that ensure no leakage, even in the harsh conditions of space.

- Oil and Gas: In an industry where safety and efficiency are paramount, spring energized seals play a crucial role in preventing spills and maintaining equipment reliability. PCT has NACE compliant spring energizers.

- Pharmaceuticals: Ensuring contamination-free environments is vital. With seals from Polymer Concepts, pharmaceutical companies can ensure their products remain pure and safe.

- Medical Device: uses FDA compliant seal jacket materials which can withstand autoclave cleaning

Selecting and Implementing the Right Seal

Guidance on Selection: Consider factors like operating conditions, required lifespan, and specific application needs. Consulting with experts, like those at Polymer Concepts, can ensure you make the right choice.

Installation: Even the best seal needs proper installation and upkeep. Appropriate installation techniques are critical for seal performance, Polymer Concepts offers detailed guidance and support in this regard.

Spring energized seals, with their myriad advantages, are paving the way for safer and more efficient operations across industries. As pioneers, Polymer Concepts continues to set industry standards, ensuring businesses have access to top-notch sealing solutions.

Ready to explore the world of advanced sealing solutions? Dive deep into precision, quality, and performance with Polymer Concepts. Discover more about how we can revolutionize your sealing needs.

Detailed insights, specific product features, and proprietary technologies related to Polymer Concepts would require a more in-depth examination of their offerings and consultations with the company's experts.