PCTI Design Team

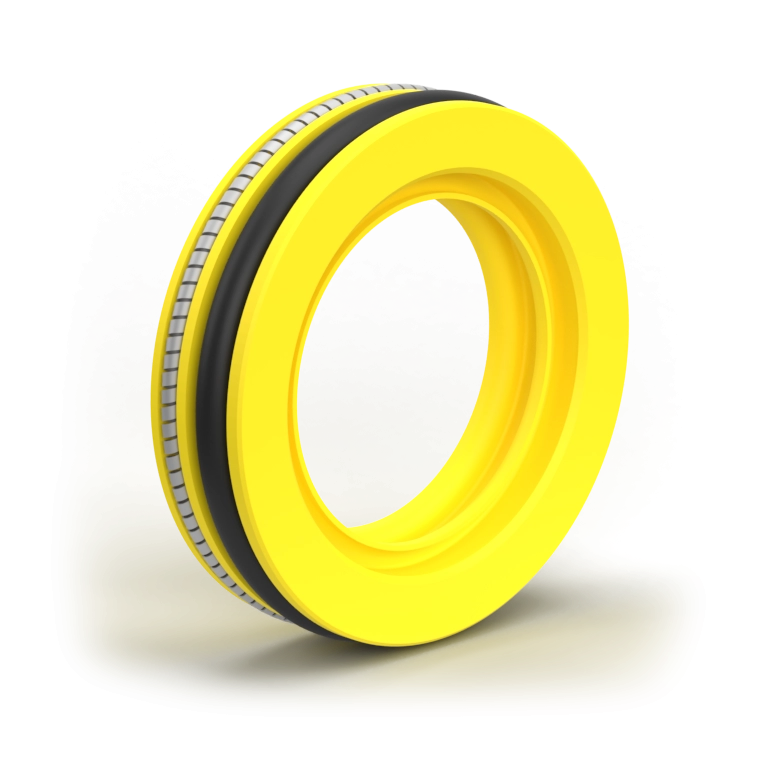

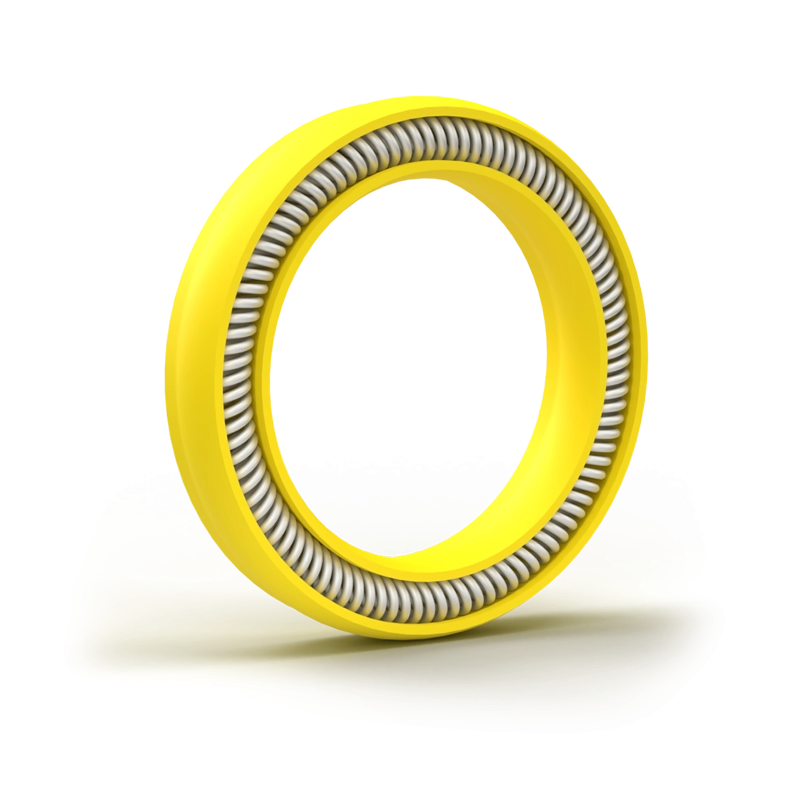

ROTARY SEALS

What are Rotary Seals?

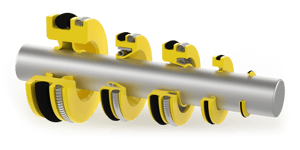

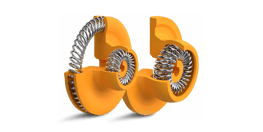

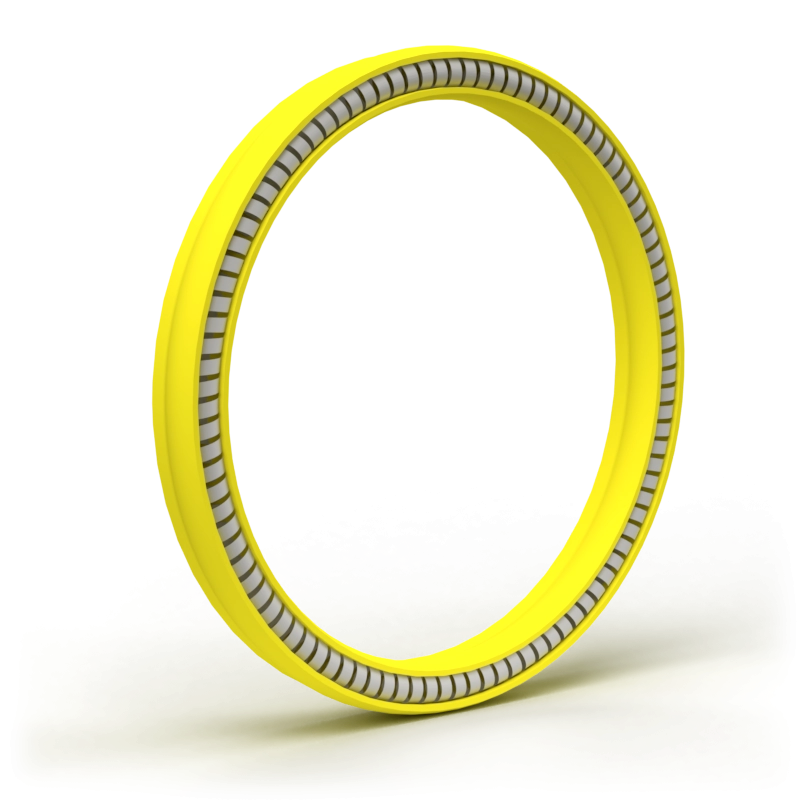

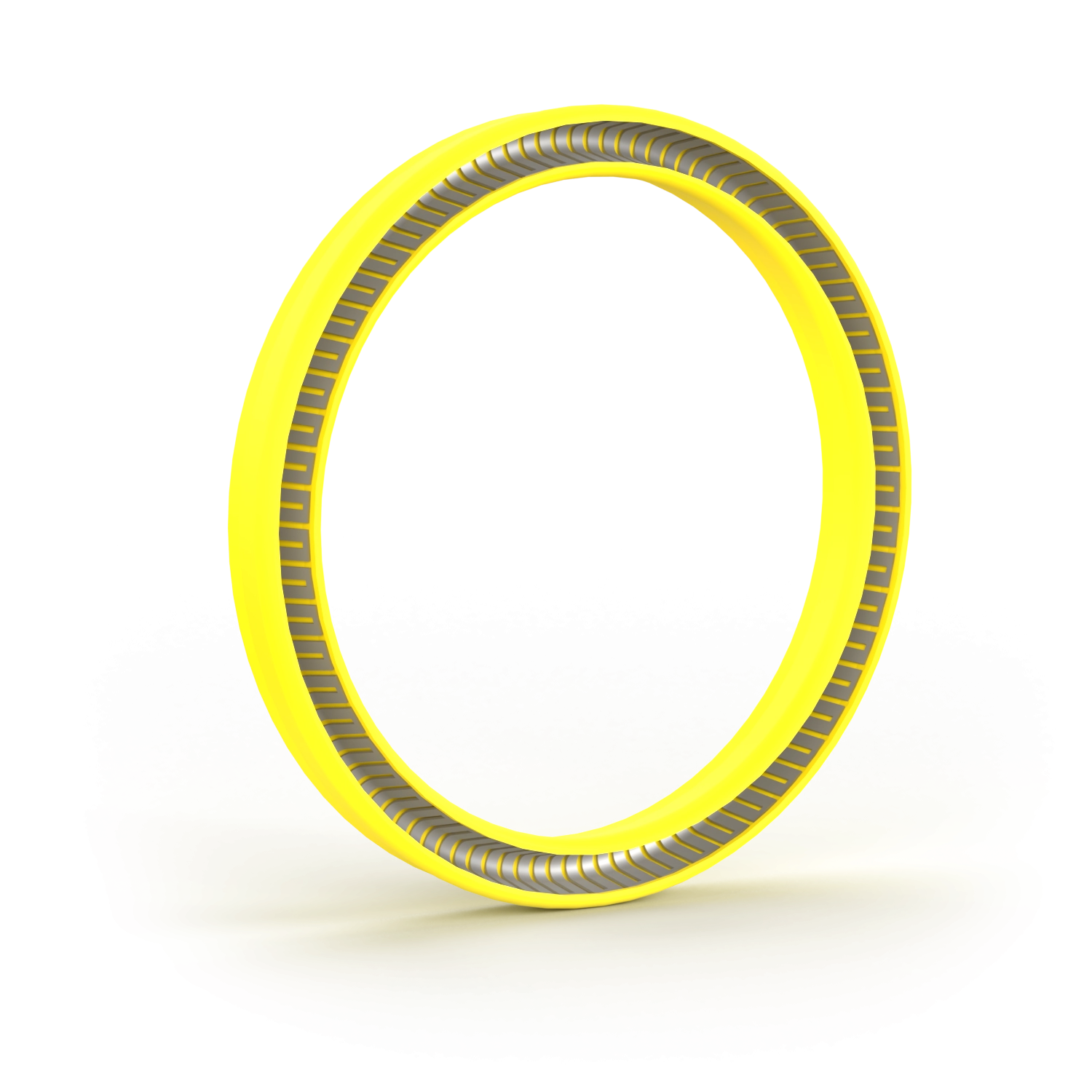

Rotary seals are seals that are used in rotary or oscillating applications. Their main purpose it to protect the bearing or an electrical motor that is used to support the shaft in rotating applications. The seal prevents the lubrication media from escaping for bearings and protect an electrical motor from liquid intrusion. The seal increases the overall service life of the equipment. The rotary seals are machined from proven profile designs to any metric or imperial diameter.

How do Rotary Seals Work?

Rotary seals are used to close the gap between stationary and rotating system components. They work by sealing the system lubricant in—typically either oil or grease—between the lip and shaft. Simultaneously, rotary seals prevent leaks and contamination by excluding dust and liquid contaminates that will damage the lubricant or the equipment. The seal’s ability to protect the lubricant while excluding contaminates increases the service life of the equipment. Our PTFE rotary seals can be used in dry environments where no lubrication is available. We suggest that you contact us to discuss the effect of surface speed and pressure on seal jacket material and design.

Common Rotary Seal Types

Benefits of Rotary Seals

Some key benefits of rotary seals include:

Protects Bearing or Electrical Motor

Tolerant to a Wide Range of Temperatures

Chemical Resistant

High Surface Speed Applications

Reliable Sealing in Dry Environments

Longer Seal Service Life

Rotary Seal Selection Considerations

When selecting and designing a rotary seal for its intended application, consider the following:

-

Surface Speed (define RPM multiplied by circumference)

-

Pressure

-

Hardness of Dynamic Material Interface

-

Surface Finish of Dynamic Material Interface

-

Shaft Dynamic Runout

-

Temperature (operating, minimum and maximum)

-

Coefficient of Thermal Expansion (CTE)

-

Media

-

Lubrication (hydrodynamic boundary layer)

-

Duty Cycle

Rotary Seal Applications

Rotary seals are an ideal choice for sealing applications across a variety of industries, including:

Industrial

- Adhesive Dispensing Equipment

- Compressors

- Cryogenic Systems

- Food Processing Pumps

- Fluid Transfer Systems

- Insulators

- Mixers

- Robotics

- Vacuum Pumps

Medical Device & Life Sciences

- HPLC/UPLC

- Surgical Tools

- Autoclave Equipment

- Instrumentation

- Hematology Analyzers

- Oxygen Concentrators

- Pharmaceutical Equipment

Aerospace

- Actuators

- Gearboxes

- Turbine Engines

- Landing Gears

- Fuel Systems

- APUs

- Cryogenic Valves

Oil & Gas

- Surface Drilling Equipment

- Downhole Tools

- Pumps and Valves

- Subsea and Deepwater Equipment

- HPHT Environments

- LWD/MWD Tools

Ready to Work With the Industry-Leading Rotary Seal Manufacturer?

Your Polymer Concepts team is here to help.

Whether you have a sales inquiry, need some customer support, would like engineering feedback, or have something to share with marketing, Polymer Concepts is here for you.

Contact us through the web form and we will happily respond to your questions or comments. You are also welcome to call us for a quicker response at 760.240.4999. We look forward to hearing from you!