PCTI Design Team

SPRING ENERGIZED SEALS

What are Spring Energized Seals?

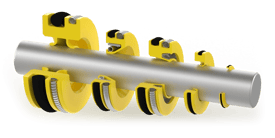

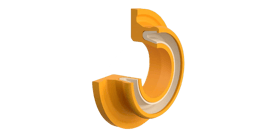

Spring energized seals are made up of two components: a polymer-based seal jacket and spring energizer. Spring energized seals are great for use in environments that are too aggressive for other types of seals, as they provide a longer service life, maintain sealing pressure, and offer extreme wear resistance.

How Do Spring Energized Seals Work?

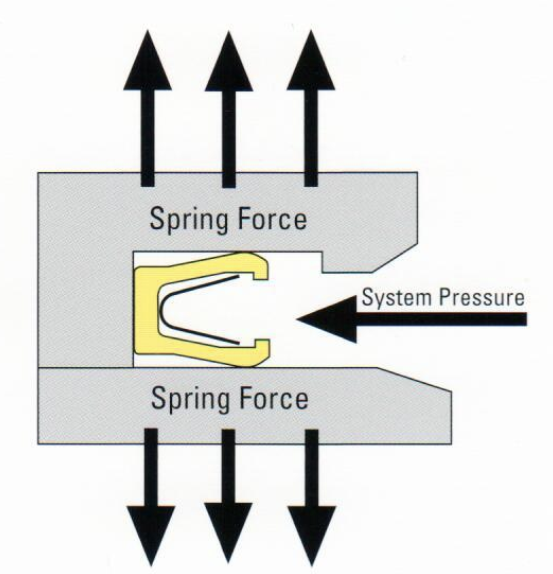

There are 3 elements for a proper a SES seal function. The first is the interference between the seal jacket and the mating surface. The forces are relatively light. The seal jacket heel must be supported for the seal to properly stay in place and the lips to function properly.

The second force is the resultant forces of the spring energizer. The spring energizer forces can be light if friction is important or heavy if leakage is the primary concern. The spring force will be higher than the force caused by interference. The spring becomes the dominant force in applications with minimal to no pressure. The spring acts as the initial energizer and prevents the media from bypassing the seal contact surface.

The third force is the media pressure. The media pressure is higher than the combination of the interference and spring energizer and becomes the dominant force in many applications.

Common Spring Energized Seal Jacket Materials

Spring energized seals are available in a variety of materials that offer enhanced benefits to meet your particular needs and application. Some common materials for spring energized seals include:

Spring Energized Seals Material Codes and Properties

|

Material Code |

Description |

Color |

Temperature Range,°F [°C] |

Tensile Strength, PSI [MPa] |

Material Data Sheets |

|

|---|---|---|---|---|---|---|

|

Polycon 01A |

Virgin PTFE |

White |

-450 [-268] |

500 [260] |

4675 [32] |

|

|

Polycon 01C |

Modified PTFE |

White |

-450 [-268] |

600 [315] |

5100 [35] |

|

|

Polycon 04 |

Lubricated Carbon-Filled PTFE |

Black |

-450 [-268] |

600 [315] |

2310 [16] |

|

|

Polyycon 050 |

PCTFE |

Translucent |

-450 [-268] |

356 [180] |

5790 [40] |

- |

|

Polycon 06 |

Lubricated Glass-Filled PTFE |

Light Grey |

-450 [-268] |

600 [315] |

2525 [17] |

|

|

Polycon 08 |

Formulated UHMWPE |

Gold |

-450 [-268] |

180 [82] |

2950 [20] |

|

|

Polycon 10 |

Polymer-Filled PTFE |

Tan |

-450 [-268] |

600 [315] |

2925 [20] |

|

|

Polycon 12 |

Lubricated Formulated PTFE |

Black |

-450 [-268] |

600 [315] |

2400 [17] |

|

|

Polycon 21 |

Lubricated Glass-Filled PTFE |

Grey |

-450 [-268] |

600 [315] |

3430 [23] |

|

|

Polycon 25 |

Virgin PEEK |

Tan |

-346 [-210] |

600 [315] |

15850 [109] |

|

Benefits of Spring Energized Seals

Some key benefits of spring energized seals include:

Chemical Compatibility

Wide Temperature Range

Vacuum to High Pressure

Low Friction in Dry Environments

Types Of Spring Energizers Used In Seals

The types of spring energizers used in spring energized seals include:

- Helical Spring Seals

- Cantilever V-Spring Seals

- Canted Coil Spring Seals (see slant coil height under deflection)

Helical Spring

The helical spring energizer design is intended for static applications due to the high unit load. It can be used in very slow or infrequent dynamic conditions when friction and wear are secondary concerns to positive sealing.

This spring energizer design produces an evenly distributed load across each individual band. Our in-house manufacturing team maintains minimal gaps between coils. This tight spacing provides continuous load, reducing potential leak paths and failures.

Helical springs are well suited for vacuum and cryogenic applications.

Cantilevered V-Spring

Cantilever V Spring Seals utilize a V-Shaped spring pressed into a seal jacket. At installation the Cantilevered V-Spring is compressed, pushing against the legs of the seal providing positive sealing pressure. This type of spring energizer has a linear load curve and significant deflection range.

Cantilevered V-Spring seals are ideal for applications whose materials resemble adhesive-like properties.

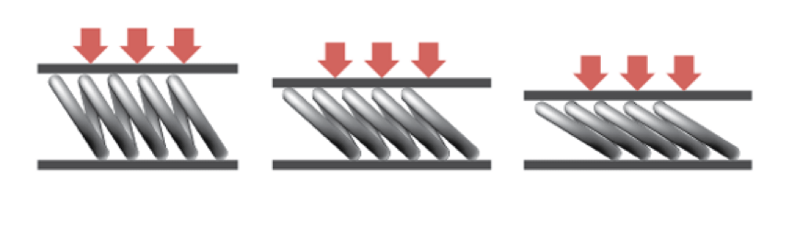

Canted Coil Spring

Advanced Slant Coil Springs are made from round wire which is coiled and formed into an elliptical shape on an inclined position. Unlike any other types of springs, Advanced Slant Coil Springs produce near constant spring force over a wide range of working deflection and provide outstanding stress properties and fatigue life.

Canted coil springs are a great option for low, repeatable friction, and wide gland tolerances.

Spring Energized Seal Applications

Spring energized seals are an ideal choice for sealing applications across a variety of industries, including:

Industrial

- Adhesive Dispensing Equipment

- Compressors

- Cryogenic Systems

- Food Processing Pumps

- Fluid Transfer Systems

- Insulators

- Mixers

- Robotics

- Vacuum Pumps

Medical Device & Life Sciences

- HPLC/UPLC

- Surgical Tools

- Autoclave Equipment

- Instrumentation

- Hematology Analyzers

- Oxygen Concentrators

- Pharmaceutical Equipment

Aerospace

- Actuators

- Gearboxes

- Turbine Engines

- Landing Gears

- Fuel Systems

- Quick Disconnects

- APUs

- Cryogenic Valves

Oil & Gas

- Surface Drilling Equipment

- Downhole Tools

- Pumps and Valves

- Subsea and Deepwater Equipment

- HPHT Environments

- LWD/MWD Tools

Ready to Work With the Industry-Leading Spring Energized Seal Manufacturer?

Your Polymer Concepts team is here to help.

Whether you have a sales inquiry, need some customer support, would like engineering feedback, or have something to share with marketing, Polymer Concepts is here for you.

Contact us through the web form and we will happily respond to your questions or comments. You are also welcome to call us for a quicker response at 760.240.4999. We look forward to hearing from you!