PCTI Design Team

PEEK SEALS

What are PEEK Seals, Bearings, & Backup Rings?

Polyether ether ketone (PEEK) is an organic thermoplastic polymer. As one of the most popular thermoplastics on the market, PEEK has a unique chemical structure that makes it incredibly strong and stable even under the harshest environments. Due to its strength and superior properties, it is commonly used in sealing applications across numerous industries.

Key Material Properties & PEEK Seal Temperature Range

PEEK has outstanding properties that present remarkable thermal, mechanical, and chemical resistance features. Here are some key material properties of PEEK:

|

Material Code |

Description |

Color |

Temperature Range,°F [°C] |

Tensile Strength, PSI [MPa] |

Material Data Sheets |

|

|---|---|---|---|---|---|---|

|

Polycon 25 |

Virgin PEEK |

Tan |

-346 [-210] |

600 [315] |

15850 [109] |

|

| * The information contained herein are typical values which falls within the normal range of properties. All information are intended for reference and comparison purposes only as general guideline for use at user discretion. They should not be used as a basis for design specifications or quality control. Polymer Concepts do not guarantee for results obtained with respect to the products. | ||||||

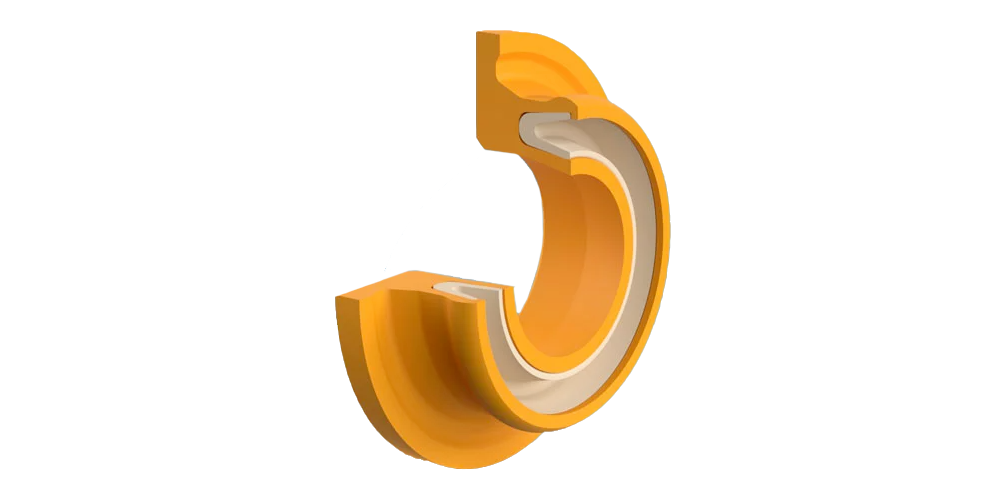

Common Seal Types

Benefits of PEEK Seals, Bearings, & Backup Rings

PEEK seals can be found in nearly every industry, performing where other plastic polymers may fall short. Some key benefits of PEEK seals include:

Low Moisture Absorption

High Temperature Resistance

Chemical Resistance

Superior Tensile Strength

Excellent Electrical Properties

Superior Creep Resistance

Abrasion Resistance

Excellent Fatigue & Stress Crack Resistance

FDA Complaint (virgin)

PEEK Seal Material Variations & Grades

PEEK is available in a variety of grades that offer enhanced benefits to meet your particular needs and application. Some typical PEEK grades include:

-

Virgin PEEK (Unfilled)

-

Glass Filled PEEK

-

Carbon Filled PEEK

-

Carbon Fiber Filled PEEK

Common PEEK Seal Types

Some common PEEK seal types include:

- Piston Ring Seals

- Ball Valve Seals

- Rotary Shaft Seals

- Ball and Butterfly Valve Seats

- Backup Rings

- Bearing and Bushings

PEEK Seal Applications

PEEK is an excellent material choice for sealing applications that require superior thermal, chemical, and mechanical properties.

Industrial

- Adhesive Dispensing Equipment

- Compressors

- Cryogenic Systems

- Food Processing Pumps

- Fluid Transfer Systems

- Insulators

- Mixers

- Robotics

- Vacuum Pumps

Medical Device & Life Sciences

- HPLC/UPLC

- Surgical Tools

- Autoclave Equipment

- Instrumentation

- Hematology Analyzers

- Oxygen Concentrators

- Pharmaceutical Equipment

Aerospace

- Actuators

- Gearboxes

- Turbine Engines

- Landing Gears

- Fuel Systems

- Quick Disconnects

- APUs

- Cryogenic Valves

Oil & Gas

- Surface Drilling Equipment

- Downhole Tools

- Pumps and Valves

- Subsea and Deepwater Equipment

- HPHT Environments

- LWD/MWD Tools

Ready to Work With the Industry-Leading PEEK Seal Manufacturer?

Your Polymer Concepts team is here to help.

Whether you have a sales inquiry, need some customer support, would like engineering feedback, or have something to share with marketing, Polymer Concepts is here for you.

Contact us through the web form and we will happily respond to your questions or comments. You are also welcome to call us for a quicker response at 760.240.4999. We look forward to hearing from you!